When a Birmingham-based retail chain requested quotes for five thousand custom shopping bags in March 2024, they received proposals from four suppliers. The spreadsheet comparison seemed straightforward: unit prices from £3.80 to £6.20, and production lead times from five to eight weeks. The procurement team sorted by lead time, cross-referenced with price, and selected a Vietnamese supplier quoting £4.10 per unit with a six-week timeline. The decision appeared rational—competitive pricing with the second-fastest delivery window. The bags were needed for a May store refresh campaign, and six weeks provided what seemed like adequate buffer time given that it was early March.

At week three, the procurement manager sent a production status inquiry. The supplier responded promptly: they were currently sourcing the custom-dyed fabric specified in the order and expected to begin production within seven to ten days. Begin production. The phrase triggered immediate concern. The six-week timeline had been interpreted as six weeks from purchase order issuance to delivery. The supplier had meant six weeks from the start of production to delivery. The company was three weeks into what they believed was a six-week timeline, only to discover that production hadn't even commenced. By the time the fabric arrived, production began, and goods shipped, the bags reached Birmingham in week ten—four weeks after the campaign launch date.

The financial impact extended beyond the £20,500 bag order. The delayed launch forced the company to postpone in-store promotions by a month, resulting in approximately £45,000 in lost revenue during what should have been a peak sales period. They'd printed point-of-sale materials referencing the original launch date, which became waste. The marketing team had coordinated social media campaigns and email blasts around the refresh timeline, creating customer expectations that couldn't be met. The total cost of the lead time misjudgment—including lost sales, wasted materials, and reputational impact—was estimated at £68,000, or roughly 3.3 times the original bag order value.

This scenario represents one of the most common yet least discussed causes of delivery failure in custom bag procurement: the systematic exclusion of pre-production lead time from supplier quotes. In our experience working with UK procurement teams over the past decade, confusion between "production lead time" and "total lead time from purchase order" accounts for approximately twenty-five percent of all timeline misses for offshore custom bag orders. The problem isn't that buyers don't ask about lead times—it's that they compare quoted timelines without understanding that "production lead time" measures only the manufacturing phase, excluding the often substantial period between purchase order issuance and the moment production actually begins.

The core issue is definitional ambiguity in how suppliers communicate timelines. When a Chinese or Vietnamese manufacturer quotes "six weeks production lead time," they're typically committing to complete manufacturing within six weeks once production starts. This is a factory-centric definition that aligns with how production facilities measure their own performance—they track the time from when a job enters the production schedule to when finished goods are ready for shipment. But buyers interpret "production lead time" as the time from purchase order issuance to delivery, which is a buyer-centric definition that includes all phases of the fulfillment process. These are fundamentally different measurements, yet procurement teams comparing quotes in a spreadsheet see "six weeks" versus "eight weeks" and conclude that the six-week supplier is faster.

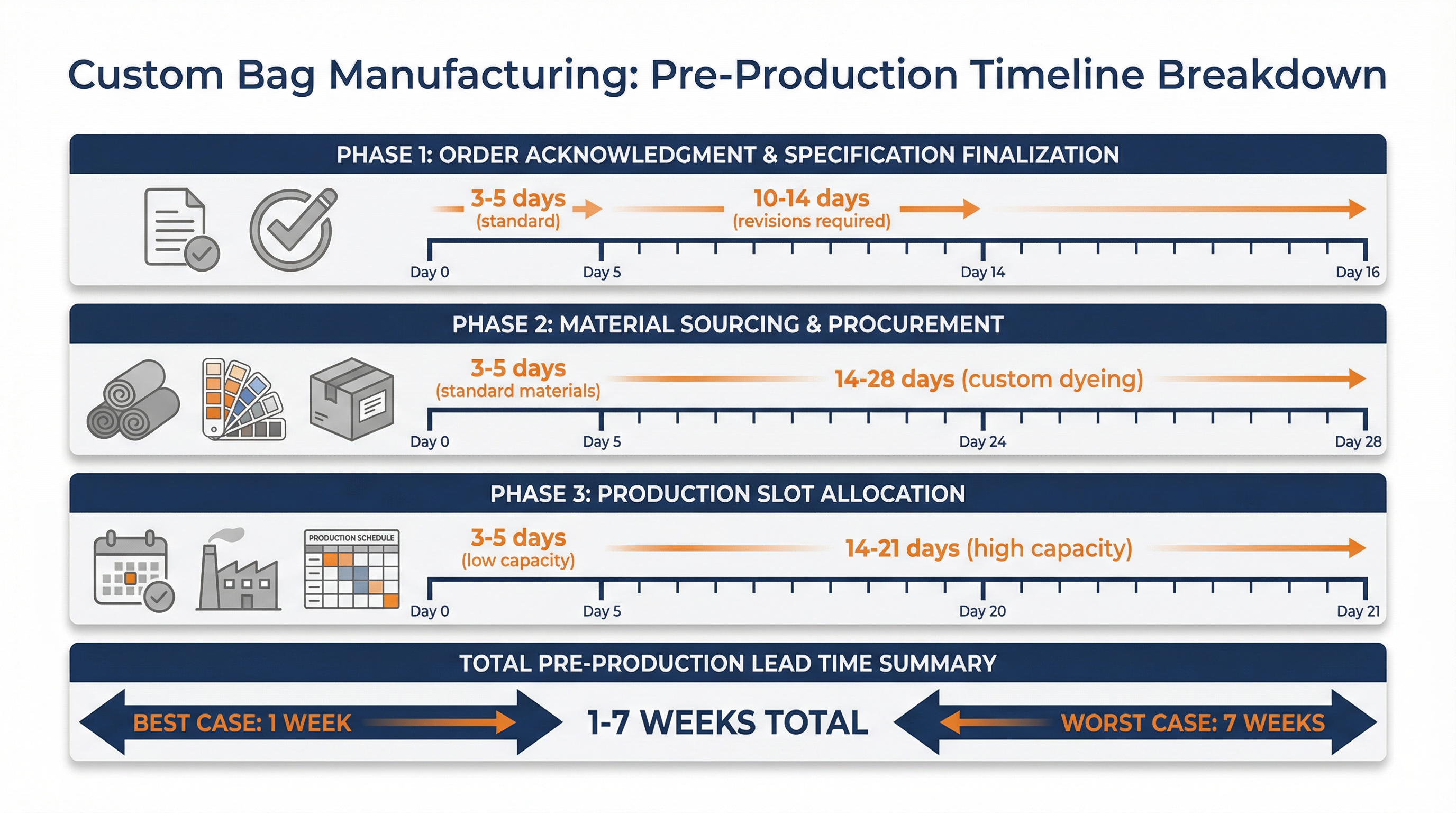

The gap between purchase order issuance and production commencement—what we'll call pre-production lead time—consists of three distinct phases, each with its own duration variability. Understanding these phases is essential to accurately comparing supplier quotes and avoiding systematic timeline underestimation.

The first phase is order acknowledgment and specification finalization. After a purchase order is issued, the supplier must acknowledge receipt, review the order details, confirm specifications, and finalize any outstanding questions about artwork, dimensions, or material requirements. For straightforward orders with standard specifications and pre-approved artwork, this phase typically takes three to five working days. For orders requiring artwork adjustments, specification clarifications, or internal approvals on the buyer's side, this phase can extend to two weeks. The duration depends less on the supplier's efficiency and more on how thoroughly the buyer prepared the order documentation before issuing the purchase order.

The second phase is material sourcing and procurement. Once specifications are finalized, the supplier must source and secure the materials required for production. This is where the distinction between standard and custom specifications becomes critical. For bags using standard materials—common fabric weights, standard colors available in the supplier's inventory, conventional handle types—material sourcing typically takes three to five days because suppliers maintain inventory of frequently used components. But for bags requiring custom specifications—Pantone-matched color dyeing, non-standard fabric weights, special handle materials, unique closure mechanisms—material sourcing can take two to four weeks. Custom color dyeing alone typically requires ten to fourteen days because the fabric mill needs to mix the dye batch, process the fabric, and allow for drying and quality control before shipping to the bag manufacturer. If the specified fabric isn't in the mill's standard product line, add another week for the mill to source the base material before dyeing can begin.

The third phase is production slot allocation. Even after materials arrive at the factory, production doesn't begin immediately. Factories operate on production schedules that allocate manufacturing capacity across multiple clients and orders. When an order is ready for production, it enters a queue and waits for an available production slot. The duration of this wait depends primarily on the factory's capacity utilization rate. At low capacity utilization—typically under sixty percent—production slots are readily available, and orders can begin within three to five days of material arrival. At medium capacity utilization—sixty to eighty percent—the wait extends to one to two weeks as the factory balances existing commitments with new orders. At high capacity utilization—above eighty percent—the wait can reach two to three weeks, particularly during peak seasons when factories prioritize larger orders or long-standing client relationships.

When these three phases are combined, the total pre-production lead time ranges from as little as one week in the best-case scenario to as much as seven weeks in the worst-case scenario. The best case assumes standard specifications with materials in stock, low factory capacity utilization, and no specification clarifications required. The worst case assumes full custom specifications requiring color dyeing and special materials, high factory capacity utilization during peak season, and multiple rounds of artwork or specification revisions. The typical case for custom bags with moderate customization—custom logo printing on standard bag styles with Pantone color matching—falls in the two-to-three-week range for pre-production lead time.

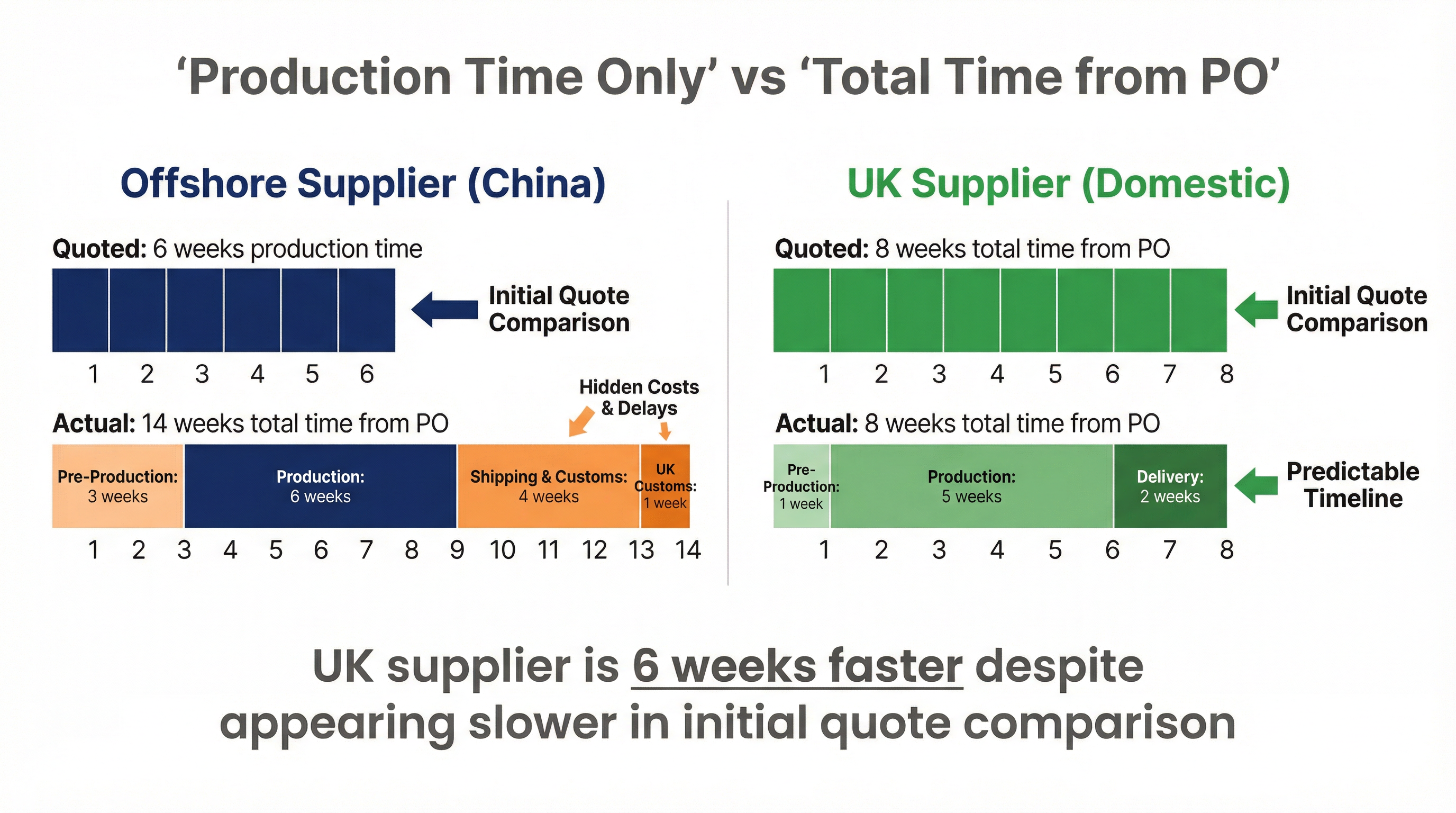

The procurement error occurs when buyers compare quotes without normalizing for what the quoted timeline actually measures. Consider a scenario where a UK buyer receives three quotes for custom tote bags. Supplier A, based in China, quotes £4.20 per unit with "six weeks production lead time." Supplier B, based in Vietnam, quotes £4.50 per unit with "seven weeks manufacturing time." Supplier C, based in the UK, quotes £7.80 per unit with "eight weeks total lead time from purchase order." The buyer's spreadsheet shows Supplier A as fastest and cheapest, Supplier B as middle ground, and Supplier C as slowest and most expensive. Based on this comparison, most procurement teams would select Supplier A or B.

But this comparison is structurally invalid because the three quotes measure different milestones. Supplier A's "six weeks production lead time" likely means six weeks from production start to goods ready for shipment, excluding pre-production time and international shipping. If we add typical pre-production time of three weeks for custom specifications and medium factory capacity, plus four weeks for sea freight and one week for UK customs clearance, the true timeline from purchase order to delivery is fourteen weeks. Supplier B's "seven weeks manufacturing time" similarly excludes pre-production and shipping, resulting in a true timeline of approximately fifteen weeks. Supplier C's "eight weeks total lead time from purchase order" is the only quote that measures door-to-door delivery, making it the fastest option by six to seven weeks despite appearing slowest in the initial comparison.

The misjudgment is compounded by how request-for-quotation templates are structured. Most RFQ forms ask suppliers to provide "lead time" or "production time" without specifying whether this should measure from purchase order issuance or from production commencement, and without requiring suppliers to break down the timeline into its component phases. Suppliers respond with their standard quoting practice, which for offshore manufacturers typically means production time only, because that's the portion of the timeline they directly control. UK-based suppliers more commonly quote total time from purchase order because their customers expect door-to-door service and because domestic production eliminates the long international shipping phase that offshore suppliers need to coordinate with freight forwarders.

The result is that buyers comparing offshore and domestic quotes systematically underestimate offshore timelines by two to seven weeks, creating a false perception that offshore production is faster than it actually is. This bias toward offshore suppliers isn't based on actual delivery speed—it's an artifact of how timelines are communicated and compared. When timelines are normalized to the same measurement basis—total time from purchase order issuance to delivery at the buyer's facility—the speed advantage of offshore production often disappears or even reverses, particularly for orders under two thousand units where UK production's shorter pre-production and shipping phases outweigh offshore production's lower per-unit manufacturing time.

Understanding why suppliers quote production time rather than total time requires considering the operational realities of manufacturing. From a factory's perspective, pre-production time isn't under their direct control. Material sourcing depends on their suppliers' lead times, which vary based on market conditions, raw material availability, and the complexity of custom specifications. Production slot allocation depends on the factory's overall order book, which fluctuates based on seasonal demand patterns and client ordering behavior. Artwork finalization depends on the buyer's internal approval processes, which can take days or weeks depending on the buyer's organizational structure. Because these variables are outside the factory's direct control, quoting them as part of "production lead time" creates risk that the factory will be held accountable for delays they can't prevent.

By quoting only the production phase—the time from when materials are ready and a production slot is available to when finished goods are packed and ready for shipment—factories are quoting the portion of the timeline they can reliably control and commit to. This makes operational sense from the factory's perspective, but it creates systematic misunderstanding when buyers interpret "production lead time" as total lead time. The solution isn't to demand that factories quote total time—that would simply shift the risk of pre-production delays onto suppliers, who would respond by adding large buffer times to their quotes, making accurate planning impossible. The solution is for buyers to structure their RFQ process to require suppliers to break down timelines into discrete phases: pre-production time, production time, and shipping time.

A properly structured RFQ for custom bags should ask suppliers to provide five timeline components. First, order acknowledgment and specification finalization time: how long from purchase order issuance to confirmed specifications and approved artwork. Second, material sourcing time: how long to source and receive the specified materials, broken down by standard versus custom specifications. Third, production slot allocation time: how long from material arrival to production commencement, with estimates for different capacity utilization scenarios. Fourth, production time: how long from production start to finished goods ready for shipment. Fifth, shipping and customs clearance time: how long from factory gate to delivery at the buyer's specified address, including customs clearance for international shipments.

When suppliers are required to break down timelines this way, several benefits emerge. First, it becomes immediately obvious which suppliers are quoting production time only versus total time, eliminating the comparison error. Second, buyers can identify which phases drive timeline variability and structure their procurement process to minimize delays in those phases—for example, by finalizing artwork before issuing the purchase order to eliminate the specification finalization phase, or by selecting standard color options to reduce material sourcing time. Third, buyers can assess supplier transparency and operational sophistication based on how thoroughly they address each phase. Suppliers who provide detailed, realistic estimates for each phase demonstrate better process understanding than suppliers who provide a single aggregate number without breakdown.

For UK businesses specifically, pre-production lead time misjudgment intersects with post-Brexit customs complexity in ways that compound timeline risk. Before Brexit, customs clearance for goods entering the UK from EU suppliers typically added one to two days to delivery timelines. After Brexit, customs clearance for all non-UK goods—including from EU suppliers—now adds three to five days, and in cases where documentation is incomplete or tariff classifications are disputed, clearance can extend to two weeks. Many offshore suppliers quoting "production lead time" in 2024 are still using pre-Brexit shipping time estimates, which means their quoted timelines underestimate true delivery time by an additional two to three days even after accounting for pre-production time. Buyers who don't explicitly ask "does your shipping time estimate include current UK customs clearance duration?" are systematically underestimating total timeline by another three to five days on top of the pre-production time exclusion.

The practical implication for UK procurement teams is that any offshore supplier quoting "production lead time" or "manufacturing time" without explicitly stating "from purchase order issuance" should be assumed to be quoting production time only, excluding pre-production. As a rule of thumb, add three weeks to any offshore production time quote to estimate true timeline from purchase order to delivery for orders with moderate custom specifications and medium factory capacity utilization. For orders with extensive customization—full custom bag design, custom fabric dyeing, special hardware—add four to five weeks. For orders during peak season—typically September through November for Chinese manufacturers preparing for Western holiday demand—add an additional one to two weeks for extended production slot allocation time.

When comparing offshore and UK domestic quotes, normalize all timelines to the same measurement basis before making cost and speed comparisons. If an offshore supplier quotes six weeks and a UK supplier quotes eight weeks, ask the offshore supplier to break down their six weeks into pre-production, production, and shipping components. In most cases, the offshore supplier's true timeline from purchase order to delivery will be ten to twelve weeks, making the UK supplier's eight-week quote significantly faster despite appearing slower in the initial comparison. The cost difference may still favor offshore production, but the speed comparison should be based on accurate timelines, not on the artifact of different measurement definitions.

The broader lesson is that lead time isn't a single number—it's a multi-phase process where each phase has different drivers, different variability, and different parties responsible for execution. Understanding the structural factors that shape production timelines requires breaking down the timeline into its component phases and understanding which factors influence each phase's duration. Pre-production lead time is often the largest source of timeline variability and the most commonly excluded component in supplier quotes, making it the single most important phase for buyers to explicitly account for when comparing quotes and planning delivery schedules.

For the Birmingham retail chain that ordered bags in March expecting May delivery, the lesson was expensive but clear. In subsequent procurement cycles, they restructured their RFQ template to require suppliers to provide timeline breakdowns for pre-production, production, and shipping phases separately. They also moved their artwork approval process earlier in the procurement cycle, completing all design finalization before issuing purchase orders to eliminate the specification finalization phase from pre-production time. These changes reduced their average timeline miss rate from thirty-five percent to under ten percent, and more importantly, eliminated the large misses—the four-to-six-week delays that disrupt campaigns and damage customer relationships. The cost of implementing these process changes was minimal. The benefit, measured in avoided delays and protected revenue, was substantial.