Custom bag production in the UK typically ranges from 7-10 working days for simple logo printing on stock items, to 10-14 weeks for fully bespoke offshore manufacturing. The actual timeline depends on six critical factors: production location (UK vs overseas), customization complexity (logo-only vs full design), material sourcing requirements, order volume, approval process efficiency, and seasonal capacity constraints. For UK businesses, the decision isn't just about speed—it's about balancing lead time against cost, risk, and quality requirements within the constraints of your event calendar and budget.

Why Lead Time Planning Is a Critical Decision for UK Businesses

When a London-based marketing agency approached us in September 2024 about custom tote bags for a November product launch, they assumed four weeks would be sufficient. They'd found a supplier quoting "4-6 weeks offshore production," which seemed to align with their timeline. What they hadn't accounted for was the three-week sample approval process within their own organization, the two-week material sourcing delay due to their specific Pantone colour requirement, and the five-day customs clearance hold at Felixstowe due to incomplete documentation. The bags arrived on December 3rd—three weeks after their launch event.

The financial impact was significant. Beyond the £8,500 they'd spent on the bags themselves, they incurred £12,000 in rescheduled venue costs, £6,000 in reprinted marketing materials with new dates, and an estimated £25,000 in lost revenue from the delayed campaign. The total cost of the lead time misjudgment was £51,500, or roughly six times the original bag order value.

This scenario isn't unusual. In our experience working with UK procurement teams over the past 15 years, lead time miscalculation is the single most common cause of promotional merchandise project failure, accounting for approximately 40% of all delivery issues we've observed. The problem isn't that businesses don't ask about lead times—it's that they don't understand the variables that determine whether a quoted timeline will hold, or how to structure their procurement process to minimize delay risk.

For UK businesses specifically, lead time planning intersects with three critical decision areas that directly impact budget control, brand reputation, and regulatory compliance. Understanding these intersections is essential before evaluating specific timeline options.

Budget Control: Lead time directly affects unit cost through three mechanisms. First, expedited production typically carries a 30-60% premium over standard timelines, which can transform a £4,500 order into a £6,750 commitment. Second, air freight for urgent shipments costs approximately 4-6 times more than sea freight, adding £2-3 per unit for a typical 1,000-unit order. Third, rush fees for UK domestic production (screen printing, heat transfer) typically add 20-40% to the base price. When these costs compound, a "quick turnaround" decision can increase total project cost by 80-120% compared to planning with adequate lead time.

Brand Reputation: Missing a launch date, conference, or corporate gifting deadline doesn't just delay the campaign—it signals organizational dysfunction to your target audience. When a financial services firm we worked with in 2023 failed to deliver custom bags for their annual client appreciation event, they had to substitute generic alternatives purchased at retail. The cost wasn't just the £15,000 in wasted custom bag investment—it was the reputational damage of presenting clients with visibly off-brand merchandise that undermined their positioning as a premium service provider.

Regulatory Compliance: UK businesses face specific compliance requirements that affect lead time planning. Since October 2023, the Extended Producer Responsibility (EPR) regulations require businesses to report packaging data and pay fees for custom bags that will be distributed to end consumers. This compliance process adds 2-3 weeks to project timelines if not planned in advance. Similarly, the UK Plastic Packaging Tax (effective April 2022) requires documentation proving that plastic components contain at least 30% recycled content, which can add 1-2 weeks to material sourcing if suppliers need to provide certification. Businesses that don't account for these compliance timelines risk either project delays or regulatory penalties.

Understanding the UK Custom Bag Production Landscape

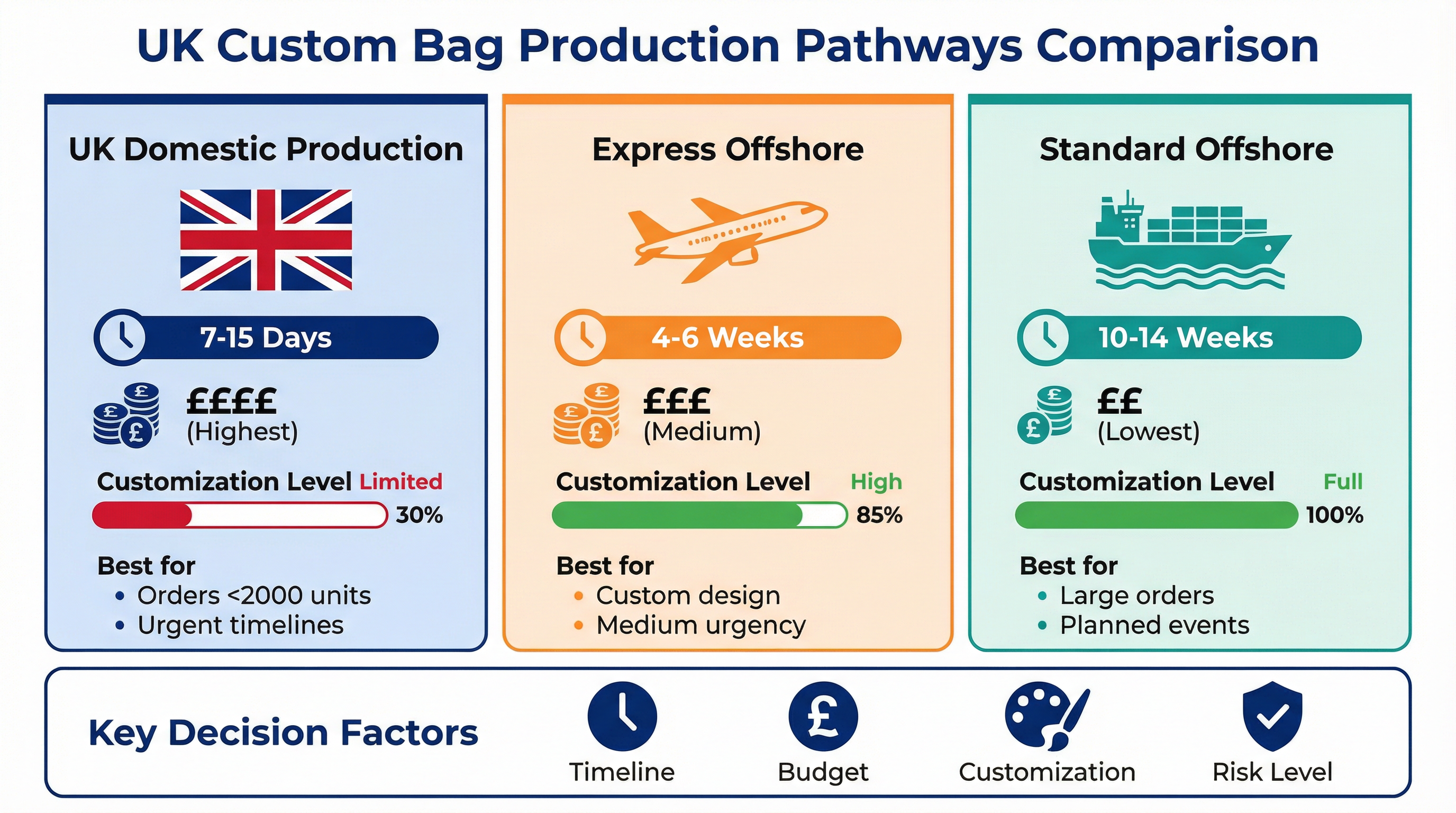

The UK market offers three distinct production pathways, each with fundamentally different timeline structures, cost implications, and risk profiles. Choosing the wrong pathway for your specific requirements is the most common cause of lead time failure.

UK Domestic Production (7-15 Working Days)

UK-based printing facilities work with pre-fabricated stock bags (canvas totes, cotton shoppers, jute bags, non-woven polypropylene) and add custom branding through screen printing, digital heat transfer, or embroidery. This pathway is fastest because it eliminates international shipping, customs clearance, and complex material sourcing.

Standard UK Production Timeline: 10-15 working days from artwork approval to delivery. This breaks down as: artwork preparation and approval (2-3 days), production slot allocation (3-5 days), printing and quality control (3-4 days), and UK domestic delivery (2-3 days). Express services can compress this to 7-10 working days by prioritizing your order in the production queue, though this typically incurs a 30-40% premium.

When UK Production Makes Sense: This pathway is optimal for orders under 2,000 units where speed matters more than unit cost, or where your event timeline is under 6 weeks. It's particularly suited to SMEs and startups that need flexibility and can't absorb the financial risk of large minimum order quantities. UK production also makes sense when your brand positioning emphasizes "Made in UK" or when you need the ability to reorder quickly based on demand testing.

UK Production Limitations: The primary constraint is customization flexibility. UK facilities work with stock bag styles, which means you can't modify dimensions, fabric weight, handle length, or structural features. Print area is limited by the bag's pre-existing construction—you typically can't print edge-to-edge, on gussets (except jute bags), or on handles. Colour matching is approximate rather than exact, as UK facilities use standard ink sets rather than custom Pantone mixing. For businesses requiring precise brand colour matching or structural customization, UK production isn't viable regardless of timeline urgency.

Offshore Express Production (4-6 Weeks)

Offshore facilities (primarily China, Vietnam, Bangladesh) offer significantly more customization flexibility—custom dimensions, fabric dyeing, edge-to-edge printing, decorative techniques (foil stamping, embossing), and structural modifications. Express offshore production uses air freight to compress the 10-14 week standard timeline to 4-6 weeks.

Express Offshore Timeline: 4-6 weeks from artwork approval to UK delivery. This breaks down as: sample production and approval (7-10 days), material sourcing and dyeing (10-14 days), production (7-10 days), quality control and packing (2-3 days), air freight (5-7 days), and UK customs clearance (3-5 days). This timeline assumes no revisions during sample approval and no material sourcing delays.

When Express Offshore Makes Sense: This pathway works for orders of 1,000+ units where you need customization that UK facilities can't provide, but your timeline is too tight for standard sea freight. It's common for corporate gifting programs where brand consistency requires exact Pantone matching, or for retail businesses launching new product lines where bag design is part of the brand identity. The economics typically work when your order value exceeds £8,000-£10,000, as the air freight premium (£2-3 per unit) becomes proportionally smaller at higher volumes.

Express Offshore Risks: The primary risk is that any delay in the approval process or material sourcing compounds quickly. If your internal stakeholders take two weeks instead of one week to approve samples, you've consumed your entire timeline buffer. Similarly, if your specified fabric isn't in stock and requires a new dyeing batch (common for custom Pantone colours), this can add 14-21 days and push you outside the 4-6 week window. We've seen approximately 35% of express offshore orders experience some form of delay, most commonly due to extended approval processes rather than factory issues.

Standard Offshore Production (10-14 Weeks)

Standard offshore production uses sea freight instead of air freight, which reduces shipping costs by 75-80% but extends timeline by 5-6 weeks. This is the most cost-effective pathway for orders over 2,000 units where timeline flexibility exists.

Standard Offshore Timeline: 10-14 weeks from artwork approval to UK delivery. The production stages are identical to express offshore (sample approval, material sourcing, production, QC), but sea freight adds 35-45 days compared to air freight's 5-7 days. UK customs clearance for sea freight shipments typically takes 5-7 days rather than 3-5 days due to higher container volumes at ports.

When Standard Offshore Makes Sense: This pathway is optimal for planned corporate gifting programs (Christmas, client appreciation events), retail inventory builds, or any scenario where you have 4-6 months of planning lead time. It's the default choice for enterprises with predictable demand patterns and established procurement processes. The unit cost savings (30-50% lower than UK production, 15-25% lower than express offshore) make this the most economically efficient pathway when timeline constraints allow.

Standard Offshore Planning Requirements: The critical success factor is starting early enough that delays don't cascade into missed deadlines. We recommend adding a 25-30% timeline buffer to the quoted 10-14 weeks, which means initiating procurement 14-18 weeks before your need-by date. This buffer accounts for extended approval cycles, material sourcing delays, and seasonal capacity constraints.

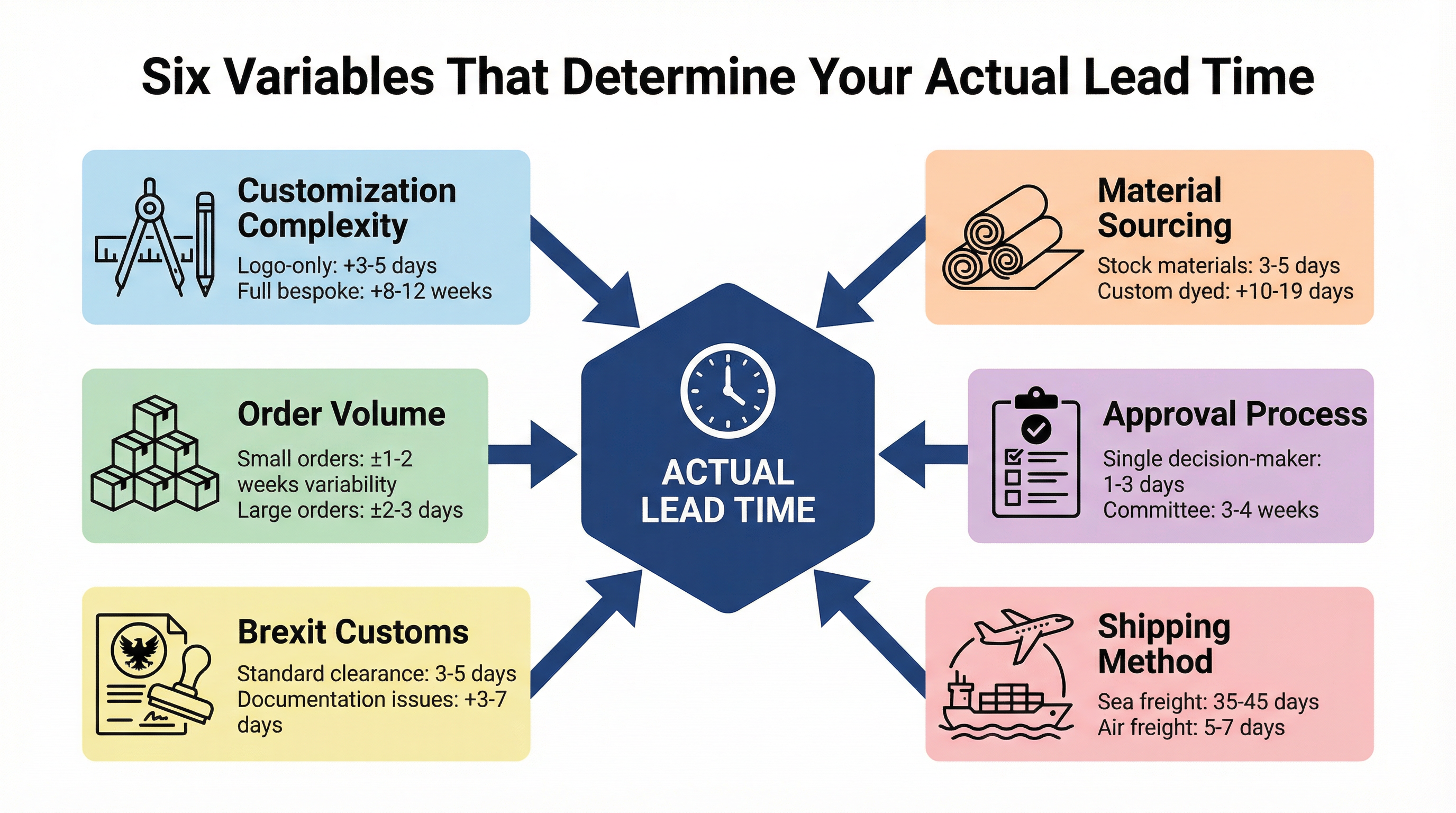

The Six Variables That Determine Your Actual Lead Time

Quoted lead times are starting points, not guarantees. The actual timeline your project experiences will be determined by how these six variables play out in your specific situation.

Variable 1: Customization Complexity

The spectrum runs from simple logo printing (fastest) to fully bespoke bag development (slowest). Each level of customization adds specific time requirements that compound across the production process.

Logo-Only Printing (simplest): Adding your logo to a stock bag via screen printing or heat transfer. Timeline impact: minimal (adds 3-5 days to base production time). This is the fastest option because it requires no structural changes, no material sourcing, and minimal sample approval.

Custom Colour Matching: Matching your brand's specific Pantone colour through fabric dyeing or custom ink mixing. Timeline impact: adds 10-14 days for fabric dyeing, 3-5 days for custom ink mixing. Fabric dyeing is the larger delay because dye houses typically work in minimum batches (500-1,000 meters), which means your order may wait for other orders to fill the batch.

Structural Modifications: Changing bag dimensions, handle length, gusset width, pocket placement, or closure mechanisms. Timeline impact: adds 14-21 days for pattern development and first sample production. Each revision cycle adds another 10-14 days. We've seen structural customization projects require 3-4 sample iterations, which can extend timelines by 6-8 weeks beyond standard production.

Decorative Techniques: Foil stamping, embossing, debossing, appliqué, or multi-colour printing. Timeline impact: adds 7-10 days for technique setup and testing. These techniques require specialized equipment and operator skill, which means they can only be performed at specific facilities. If your primary factory doesn't have the capability, your bags may need to be transferred to a secondary facility, adding another 5-7 days in logistics.

Variable 2: Material Sourcing and Availability

Material availability is the most unpredictable variable in lead time planning, and it's where most timeline failures occur. The issue isn't that materials are unavailable—it's that specific materials in specific colours at specific quality grades may not be in stock when your order is placed.

Stock Materials (cotton canvas, jute, non-woven polypropylene in standard colours): These are held in inventory by fabric suppliers and can typically be sourced within 3-5 days. If you're flexible on exact colour shade (accepting "navy" rather than "Pantone 533C"), material sourcing adds minimal time.

Custom-Dyed Fabrics: If your brand requires exact Pantone matching, fabric must be custom-dyed. Dye houses work in minimum batches, which means your order may wait 7-14 days for other orders to accumulate before the batch runs. After dyeing, fabric requires 3-5 days for drying and quality inspection. Total timeline impact: 10-19 days.

Specialty Materials (organic cotton, recycled polyester, cork fabric, waxed canvas): These materials are produced in smaller volumes and may not be in stock. Lead time for specialty materials ranges from 14-30 days if they need to be ordered from the material manufacturer. For UK businesses prioritizing sustainability, this is a common delay point—organic cotton and recycled polyester typically add 2-3 weeks to standard timelines.

The practical implication: if your project requires any custom materials or specialty components, add 14-21 days to the quoted timeline as a buffer. This buffer accounts for the reality that "in stock" often means "available in 7-10 days" rather than "shipping today."

Variable 3: Order Volume and Factory Capacity

Factory capacity isn't infinite, and your order's priority in the production queue depends on its size relative to the factory's economic thresholds. Understanding this dynamic is essential for realistic timeline planning.

Small Orders (100-500 units): These orders are typically treated as "filler work"—they're slotted into production gaps between larger committed orders. This means your quoted lead time is best-case scenario, assuming a gap opens up when expected. In practice, small orders experience higher timeline variability (±1-2 weeks) because they're deprioritized if larger orders run long.

Medium Orders (500-2,000 units): These orders typically receive dedicated production slots, which means more predictable timelines. However, they're still vulnerable to being bumped if a major customer (5,000+ unit order) needs urgent capacity. Timeline variability: ±3-5 days.

Large Orders (2,000+ units): These orders receive priority slot allocation and dedicated quality control resources. Timeline variability is lowest (±2-3 days) because factories protect these relationships.

Seasonal Capacity Constraints: Factory capacity isn't constant throughout the year. Three periods create significant capacity pressure:

-

September-November (Q4 preparation): UK businesses ordering Christmas corporate gifts create peak demand. Factories are at 90-100% capacity, which means longer lead times (add 1-2 weeks) and less flexibility for rush orders.

-

January-February (Chinese New Year): Most offshore factories shut down for 2-3 weeks during CNY. Orders placed in December may not begin production until March, effectively adding 6-8 weeks to standard timelines.

-

June-August (UK summer holidays): While factories remain operational, UK-side approval processes slow down as key stakeholders take holiday. This extends sample approval cycles from 1 week to 2-3 weeks, adding 7-14 days to total timeline.

Variable 4: Approval Process Efficiency

The most underestimated timeline variable is your own organization's approval process. In our experience, internal approval delays account for 40-50% of all lead time failures, far exceeding factory delays or shipping issues.

Single Decision-Maker (SME, startup): If one person can approve samples and artwork, approval cycles take 1-3 days. This is the fastest scenario and allows you to use the shortest end of quoted timeline ranges.

Multiple Stakeholders (marketing, legal, brand, procurement): If samples must circulate through multiple departments, approval cycles extend to 1-2 weeks per iteration. This is common in enterprises and adds 2-4 weeks to total timeline if you require 2-3 sample revisions.

Committee Approval (board-level, franchise networks): If approval requires scheduled meetings or consensus across multiple locations, approval cycles can extend to 3-4 weeks per iteration. We've seen corporate gifting projects require 8-12 weeks just for internal approval, which exceeds the entire production timeline.

The practical implication: map your internal approval process before requesting quotes, and add that timeline to the supplier's quoted lead time. If your approval process takes 4 weeks and the supplier quotes 6 weeks, your actual timeline is 10 weeks, not 6 weeks.

Variable 5: Brexit Customs and Compliance

Post-Brexit, UK businesses importing custom bags from the EU or non-EU countries face additional timeline and compliance requirements that didn't exist pre-2021. These requirements add 3-7 days to standard timelines and introduce delay risk if documentation is incomplete.

Customs Clearance Timeline: Goods entering the UK require customs declaration, duty calculation, and clearance before release. Standard clearance takes 3-5 working days for sea freight, 2-3 days for air freight. However, if documentation is incomplete or incorrect (wrong HS codes, missing certificates of origin, incorrect declared values), clearance can extend to 7-10 days while issues are resolved.

Common Customs Delays: Based on our experience and industry data, these are the most common customs-related delays:

-

Incorrect HS Code Classification (adds 3-5 days): Custom bags fall under multiple possible HS codes depending on material and intended use. If the supplier uses an incorrect code, UK customs will hold the shipment for reclassification.

-

Missing Certificates of Origin (adds 2-4 days): If you're claiming preferential duty rates under trade agreements, you need valid certificates of origin. If these aren't provided with the shipment, customs will hold goods until documentation arrives.

-

Plastic Packaging Tax Documentation (adds 1-3 days): If your bags contain plastic components (polypropylene, polyester), you need documentation proving recycled content percentage to determine tax liability. Missing documentation triggers holds.

The practical implication: add 5-7 days to quoted lead times for any offshore orders to account for customs clearance, and ensure your supplier provides complete documentation before shipment. Work with suppliers who have experience with UK customs requirements to minimize delay risk.

Variable 6: Shipping Method and Logistics

The final variable is how your finished bags get from the factory to your UK location. This choice has the largest single impact on timeline (and cost).

Sea Freight (35-45 days): Standard for offshore orders over 2,000 units. Cost: £0.40-£0.80 per unit. Timeline includes: factory to port (2-3 days), port loading and departure (3-5 days), ocean transit (25-30 days), UK port arrival and unloading (2-3 days), customs clearance (5-7 days), and final delivery (2-3 days).

Air Freight (5-7 days): Used for express offshore orders or urgent replenishment. Cost: £2.00-£3.50 per unit. Timeline includes: factory to airport (1-2 days), air transit (1-2 days), UK airport arrival (1 day), customs clearance (2-3 days), and final delivery (1-2 days).

Hybrid Approach (split shipment): For urgent orders with flexible volume requirements, some businesses use a hybrid approach—air freight 20-30% of the order for immediate need, sea freight the remaining 70-80% for cost efficiency.

The practical implication: shipping method is where you make the cost vs. timeline trade-off. If your event is in 6 weeks, air freight is mandatory regardless of cost. If your event is in 16 weeks, sea freight saves 60-70% on shipping costs with no timeline risk.

Strategic Lead Time Planning: Matching Timeline to Business Requirements

The question isn't "what's the lead time?"—it's "what lead time strategy aligns with my business requirements?" Different business scenarios require different approaches.

Scenario 1: Urgent Event (Need-By Date in 4-8 Weeks)

Recommended Pathway: UK domestic production (if customization is simple) or express offshore with air freight (if customization is complex).

Timeline Strategy: Work backwards from your need-by date and add 20% buffer. If your event is November 15th, your absolute latest order date is September 20th (8 weeks), but your target order date should be September 6th (10 weeks) to account for potential delays.

Cost Implications: Expect to pay 40-80% more than standard offshore production. For a 1,000-unit order, this means £6,500-£8,000 instead of £4,000-£4,500.

Risk Mitigation:

- Limit customization to logo-only or single-colour printing

- Choose stock materials in standard colours (no custom dyeing)

- Streamline internal approval (single decision-maker, pre-approved artwork)

- Request guaranteed delivery date with penalty clause

- Have contingency plan (generic bags from UK retail supplier) if primary order delays

Scenario 2: Planned Corporate Gifting (Need-By Date in 12-20 Weeks)

Recommended Pathway: Standard offshore production with sea freight.

Timeline Strategy: Initiate procurement 16-18 weeks before need-by date. This provides 12-14 weeks for production and shipping, plus 4-6 weeks buffer for approval cycles and potential delays.

Cost Implications: This is the most cost-effective pathway. For a 2,000-unit order, expect £7,000-£9,000 all-in (£3.50-£4.50 per unit), compared to £12,000-£16,000 for express offshore.

Risk Mitigation:

- Front-load approval process (complete sample approval before production starts)

- Order samples 4-6 weeks before production order to validate quality

- Build 2-3 week buffer into timeline

- Confirm material availability before placing production order

- Request weekly production updates to catch delays early

Scenario 3: Retail Inventory Build (Ongoing Replenishment)

Recommended Pathway: Standard offshore production with established supplier relationship and rolling purchase orders.

Timeline Strategy: Maintain 8-12 weeks of buffer stock and place replenishment orders on fixed schedule (e.g., quarterly). This eliminates timeline pressure and allows you to optimize for cost rather than speed.

Cost Implications: Lowest unit cost due to volume commitment and predictable ordering. For 5,000+ units annually, expect £2.80-£3.50 per unit, 30-40% lower than one-off orders.

Risk Mitigation:

- Establish "evergreen PO" with supplier (automatic replenishment at agreed intervals)

- Pre-order materials for known repeat designs (eliminates sourcing delays)

- Maintain safety stock to absorb unexpected demand spikes

- Negotiate priority capacity allocation with supplier

- Use sea freight for cost efficiency (air freight only for emergency replenishment)

Common Lead Time Mistakes and How to Avoid Them

Based on 15 years of working with UK procurement teams, these are the five most common lead time mistakes we've observed, along with specific prevention strategies.

Mistake 1: Confusing "Production Time" with "Total Timeline"

Suppliers often quote "production time" (the time bags spend in the factory) rather than "total timeline" (from order placement to UK delivery). A supplier quoting "4 weeks production" may actually mean 4 weeks in factory + 1 week material sourcing + 1 week shipping + 1 week customs = 7 weeks total.

Prevention: Always ask for "order placement to UK delivery" timeline, and request breakdown of each stage. Specifically ask: "If I place an order today, what date will the bags arrive at my UK address?"

Mistake 2: Underestimating Internal Approval Time

Procurement teams often assume sample approval will take 2-3 days, when in reality it takes 1-2 weeks due to stakeholder availability, revision requests, and meeting schedules.

Prevention: Map your approval process before requesting quotes. Identify every person who needs to approve and their typical response time. Add this timeline to the supplier's quote.

Mistake 3: Ordering During Peak Season Without Buffer

Placing orders in September-October for November-December delivery means competing for capacity with hundreds of other businesses. Factories prioritize larger orders and established customers, which means your order may be delayed.

Prevention: For Q4 delivery, place orders in June-July. If you must order in September, expect 2-3 week delays and plan accordingly.

Mistake 4: Choosing Offshore Production for Urgent Timelines

Businesses often choose offshore production for cost savings, even when their timeline is too tight. They assume "4-6 weeks" is a guarantee, when it's actually best-case scenario.

Prevention: If your need-by date is less than 8 weeks away, use UK domestic production regardless of cost. The cost premium (30-50%) is far less than the cost of missing your deadline.

Mistake 5: Not Planning for Customs Delays

Post-Brexit, customs clearance adds 3-7 days to every offshore order, but businesses often don't account for this in timeline planning.

Prevention: Add 5-7 days to quoted timelines for any offshore order. Ensure supplier provides complete customs documentation before shipment.

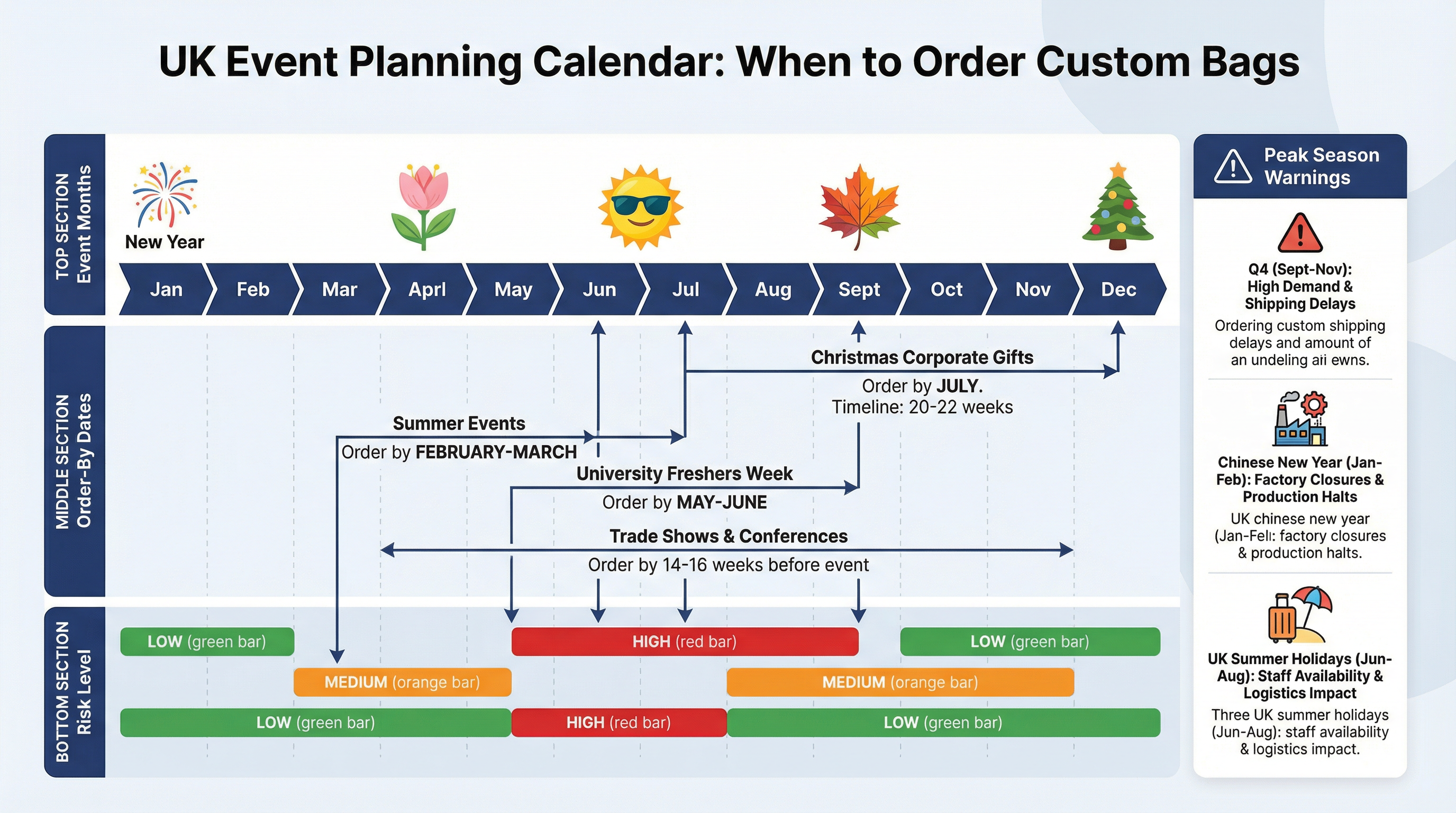

Lead Time Planning Calendar: When to Order for Common UK Events

To help UK businesses plan procurement timelines, here's a month-by-month guide for common corporate gifting and promotional events.

Christmas Corporate Gifts (delivery early December):

- Order by: Early July (20-22 weeks before)

- Why: Q4 is peak season for custom bags. Ordering in July ensures you avoid capacity constraints and have buffer for approval delays.

- Risk level: High if ordering after August

Trade Shows & Conferences (delivery varies):

- Order by: 14-16 weeks before event

- Why: Trade show bags often require custom sizing and structural features, which adds sample revision time.

- Risk level: Medium

Product Launches (delivery varies):

- Order by: 12-14 weeks before launch

- Why: Product launches often involve multiple stakeholders and extended approval processes.

- Risk level: High

Summer Events & Festivals (delivery May-July):

- Order by: February-March (12-16 weeks before)

- Why: Summer is secondary peak season. Ordering in February avoids capacity constraints.

- Risk level: Medium

Client Appreciation Events (delivery varies):

- Order by: 14-16 weeks before event

- Why: These often require premium materials and finishes, which adds material sourcing time.

- Risk level: Medium

University Freshers' Week (delivery September):

- Order by: May-June (14-16 weeks before)

- Why: Universities often order in bulk (5,000+ units), which requires dedicated production capacity.

- Risk level: High

Frequently Asked Questions

Can I get custom bags in less than 4 weeks?

Yes, but with significant limitations. UK domestic production can deliver in 7-10 working days, but you're limited to stock bag styles with logo-only printing. Full customization (custom colours, structural changes, decorative techniques) requires 4-6 weeks minimum, even with express offshore production and air freight.

What's the fastest possible turnaround time?

For logo-only printing on stock bags, some UK suppliers offer 3-5 day express service. However, this requires: (1) artwork ready for production (no revisions), (2) standard ink colours (no Pantone matching), (3) premium pricing (50-80% above standard rates), and (4) availability in the production queue (not guaranteed during peak season).

How much does expedited production cost?

Expedited fees typically add 30-60% to the base unit price. For example, if standard production is £4.00 per unit, express production is £5.20-£6.40 per unit. Air freight adds another £2.00-£3.50 per unit compared to sea freight. Total premium for express offshore: 80-120% above standard offshore production.

What happens if my bags arrive late?

This depends on your contract terms. Most suppliers don't offer delivery guarantees unless explicitly negotiated. If timeline is critical, request a guaranteed delivery date with penalty clause (e.g., 10% refund for each week of delay). This costs 5-10% more but provides recourse if delays occur.

How do I compress the timeline if I'm running late?

Four strategies: (1) Simplify customization (logo-only instead of full custom), (2) Accept stock materials (no custom dyeing), (3) Streamline approval (single decision-maker), and (4) Pay for air freight. These can compress 12-14 weeks to 6-8 weeks, but expect 60-100% cost increase.

Should I order samples before placing a production order?

Yes, especially for first-time orders or complex customization. Samples cost £50-£150 but prevent expensive mistakes. Sample timeline: 7-10 days for UK production, 14-21 days for offshore production. Factor this into your total timeline—if you need delivery in 12 weeks and samples take 3 weeks, you only have 9 weeks for production.

Next Steps: How to Plan Your Custom Bag Order

Lead time planning isn't just about asking "how long does it take?"—it's about understanding the variables that determine whether quoted timelines will hold, and structuring your procurement process to minimize delay risk.

The most important decision you'll make is choosing the right production pathway for your specific requirements. If you're unsure whether UK domestic, express offshore, or standard offshore makes sense for your timeline and budget, we can help you evaluate options based on your specific event date, customization requirements, and risk tolerance.

Our team works with UK businesses to structure custom bag procurement that balances lead time, cost, and quality within the constraints of your event calendar. We can provide detailed timeline breakdowns, identify delay risks specific to your project, and recommend strategies to ensure your bags arrive when you need them.

Get in touch with our team to discuss your specific requirements and receive a detailed timeline assessment for your project.