When a Manchester retail chain placed their September order for 3,000 custom shopping bags—eight weeks before Black Friday—they used the same supplier who had delivered flawlessly in March. The quote came back at "eight weeks," identical to their spring order. The bags arrived three days before Christmas, five weeks after Black Friday weekend had passed. The supplier's response: "Q4 is always busy." The buyer's question: "Then why did you quote eight weeks?"

This scenario repeats across hundreds of UK procurement teams every autumn, and it stems from a misjudgment that is rarely discussed in supplier negotiations: the assumption that lead time quotes are season-agnostic. When suppliers provide a timeline in September for November delivery, most buyers interpret that figure the same way they would interpret a March quote for May delivery. The supplier's production calendar, however, operates on an entirely different seasonal rhythm—and the gap between quoted and actual timelines widens dramatically during Q3 and Q4.

The core issue is not dishonesty. It is competitive pressure combined with capacity opacity. Suppliers know that quoting "twelve weeks" in September will cost them orders to competitors who quote "eight weeks." They also know that a significant portion of their client base will accept late delivery rather than cancel orders mid-production. The result is a systematic underestimation of lead times during peak season, and buyers who fail to recognize this pattern consistently miss campaign deadlines.

Understanding the structural factors that shape production timelines provides the foundation for recognizing when those timelines are likely to compress under seasonal pressure. But the misjudgment occurs earlier, at the point of quote interpretation. When a buyer receives an "eight weeks" estimate in September, they rarely ask: "Is that eight weeks assuming current capacity utilization, or eight weeks assuming the capacity utilization you will experience in October and November?" The supplier, for their part, is quoting based on current conditions—not forecasting how their production floor will look six weeks into the future when twenty other clients' orders are also hitting the line.

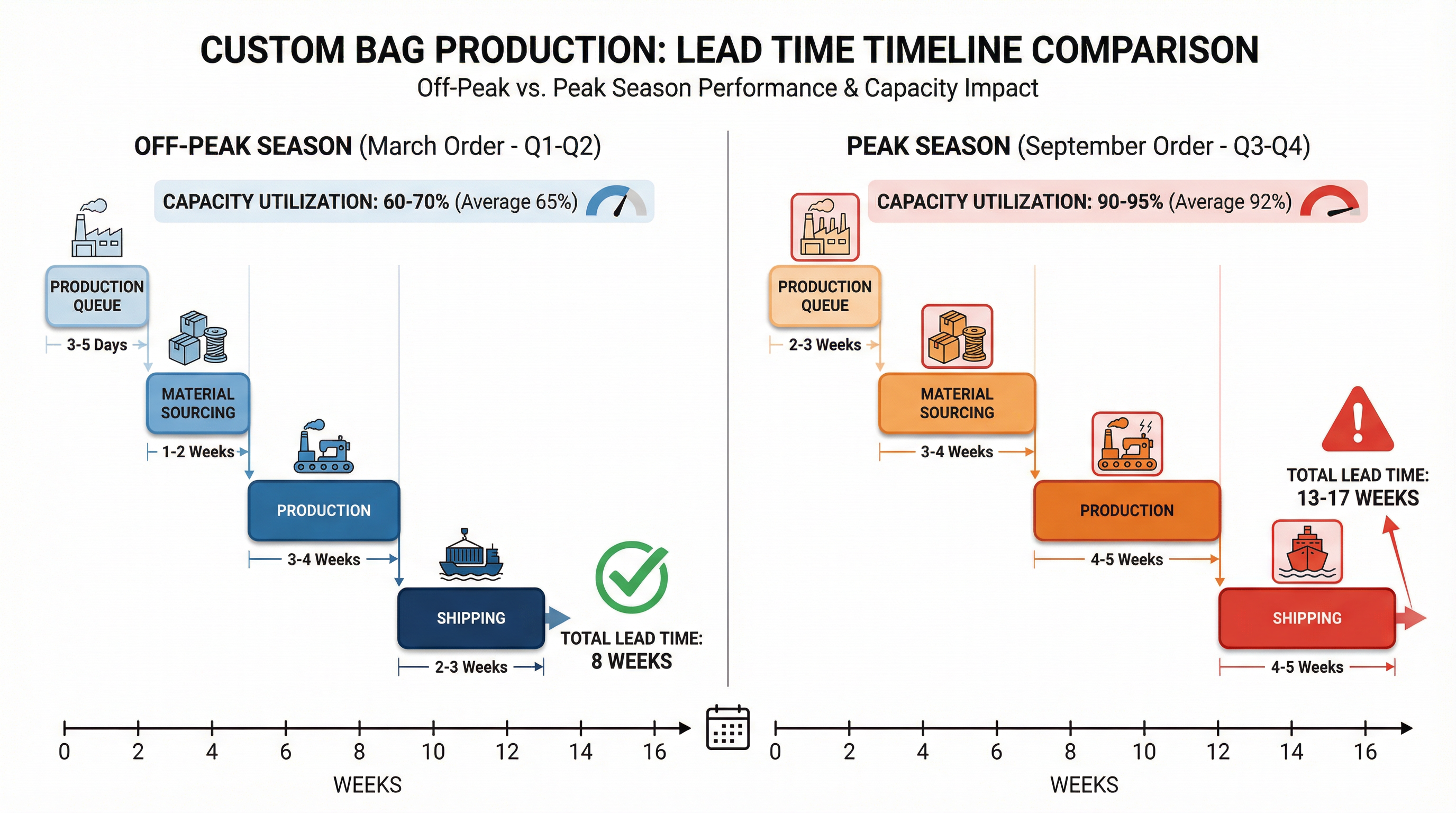

The mechanics of seasonal compression are straightforward but often invisible to buyers. During Q1 and Q2, an offshore factory producing custom bags for the UK market might operate at 60-70% capacity utilization. Production queue time—the period between order confirmation and actual production start—averages three to five days. Material sourcing for standard fabrics takes one to two weeks. Shipping from port to UK distribution centers runs on predictable schedules with minimal delays. An "eight weeks" quote in this environment is realistic and typically met.

By late September, that same factory's capacity utilization climbs to 90-95%. The production queue extends to two to three weeks because the factory is prioritizing larger clients and managing overlapping deadlines. Material sourcing now takes three to four weeks because fabric mills are also at peak capacity, and popular colors or weights face allocation constraints. Shipping delays compound as port congestion increases, freight rates spike, and carrier capacity tightens ahead of the holiday season. The same "eight weeks" quote is now structurally impossible—but the supplier continues to provide it because competitors are doing the same.

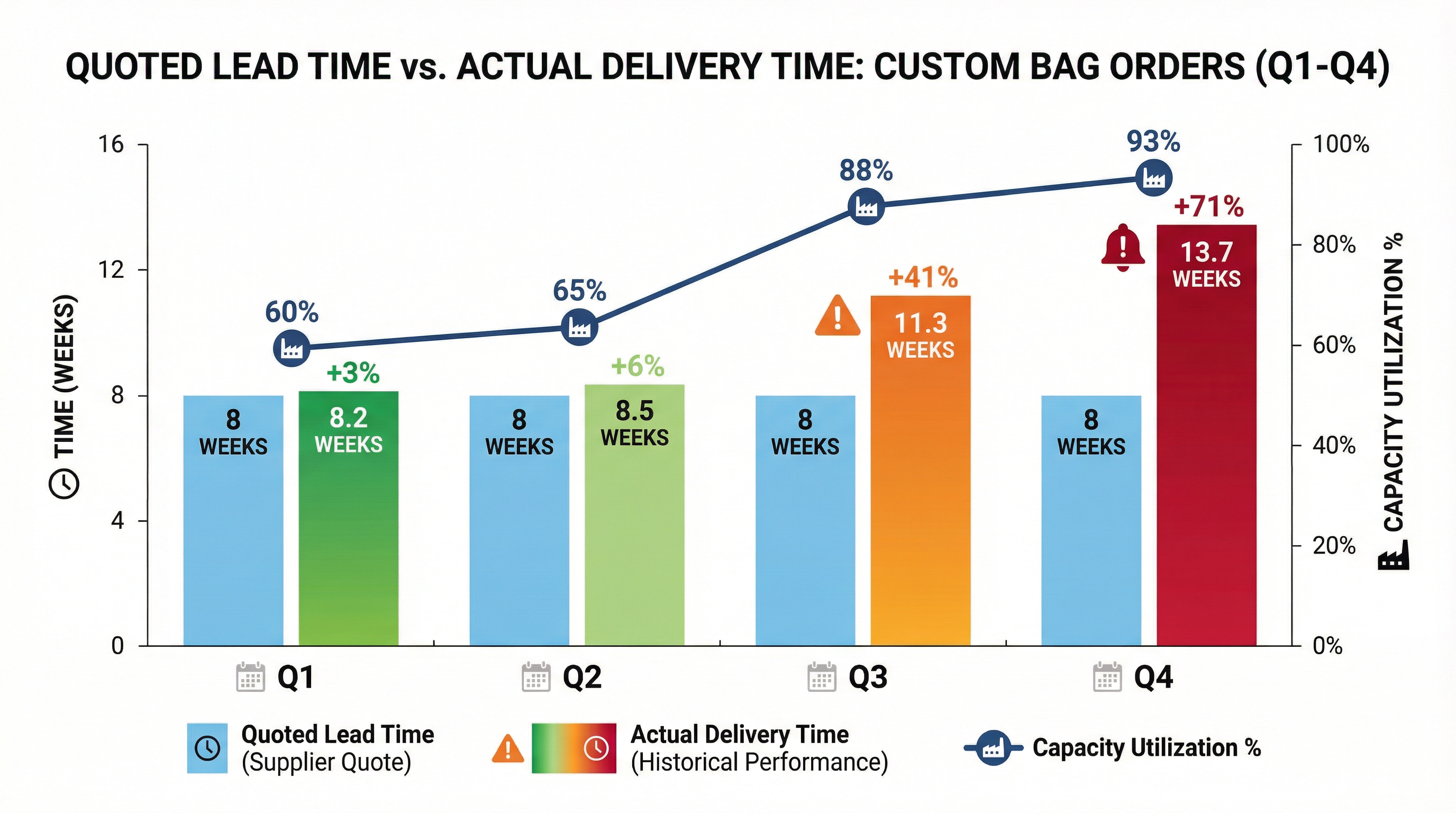

The buyer, meanwhile, has no visibility into these shifts. They see the same quote, from the same supplier, for the same product. The only variable that has changed is the order date—and most procurement teams do not track delivery performance by season. They track overall on-time rates, which average out Q1's smooth execution with Q4's systematic delays. A supplier who delivers 85% on-time across the year might deliver 95% on-time in Q1-Q2 and 70% on-time in Q3-Q4, but that seasonal variance is hidden in the aggregate metric.

The financial consequences of this misjudgment are significant. A retail chain ordering bags for Black Friday weekend expects those bags to drive incremental sales during the year's highest-traffic shopping period. When the bags arrive in mid-December, the campaign opportunity has passed. The chain either absorbs the cost of rush-ordered generic alternatives (typically 40-60% more expensive per unit) or runs the campaign without branded packaging, diluting brand impact. In the Manchester example, the delayed delivery cost an estimated £45,000 in lost Black Friday sales, plus £8,000 in expedited generic bag procurement. The supplier's penalty for late delivery—a 5% discount on the original order—amounted to £1,200, a fraction of the buyer's actual loss.

This asymmetry in risk exposure explains why suppliers do not proactively adjust their quotes during peak season. The cost of losing an order to a competitor who quotes shorter timelines far exceeds the cost of occasional late delivery penalties. Buyers, for their part, continue to accept quoted timelines at face value because they lack the data to challenge them. RFQ templates ask for "lead time" without specifying "lead time during which season" or "lead time at what capacity utilization level." The result is a persistent information gap that systematically disadvantages buyers during the most critical procurement windows of the year.

The misjudgment is compounded by relationship assumptions. Buyers who have worked with a supplier for multiple years often believe that their established relationship confers priority treatment during peak season. In practice, priority is typically determined by order size and payment terms, not relationship tenure. A £15,000 order from a three-year client competes for production slots against a £150,000 order from a new client, and the factory's scheduling logic favors the larger order. The long-term client receives the same "eight weeks" quote but finds themselves further back in the production queue than they were during off-peak months.

Another factor that obscures the seasonal compression problem is the variability of peak season timing across different product categories and geographies. UK buyers ordering custom bags for Q4 campaigns are competing for capacity with US buyers ordering for Thanksgiving and Christmas, European buyers ordering for December holidays, and Australian buyers ordering for summer season (which begins in December). The offshore factory is not managing one peak season—it is managing overlapping peak seasons from multiple markets, each with slightly different timelines and each expecting priority treatment.

Material sourcing adds another layer of complexity. Custom bags often require specific fabric weights, colors, or finishes that are not held in stock by mills. During Q1 and Q2, a mill can produce a custom fabric run within two weeks. During Q3 and Q4, that same mill is managing custom runs for dozens of clients simultaneously, and lead times extend to four to six weeks. The bag manufacturer, when quoting "eight weeks" in September, is assuming that material will arrive within two weeks—but that assumption is based on off-peak performance, not peak-season reality. When the fabric arrives in week five instead of week two, the entire production timeline shifts, but the buyer is not informed until week six or seven, when it is too late to source alternatives.

Shipping delays during Q4 are well-documented but often underestimated in lead time calculations. Port congestion at major Chinese export hubs increases transit times by one to two weeks during October and November. Freight rates spike by 30-50%, and carriers prioritize high-volume shippers, leaving smaller orders waiting for available container space. A shipment that takes three weeks port-to-port in April might take five weeks in November, but suppliers typically quote shipping time based on average annual performance, not peak-season performance.

The cumulative effect of these factors—production queue delays, material sourcing delays, and shipping delays—transforms an "eight weeks" quote into a twelve-to-fourteen-week reality. Each individual delay might be only one to two weeks, but they compound rather than overlap. The buyer who ordered in early September expecting delivery in early November receives their bags in mid-December, and the campaign opportunity has passed.

Addressing this misjudgment requires a shift in how buyers interpret lead time quotes during peak season. The first step is to explicitly ask suppliers: "What is your lead time for this order if production starts in October, and what is your lead time if production starts in March?" This question forces the supplier to acknowledge seasonal capacity constraints and provide differentiated timelines. Most suppliers will still attempt to minimize the gap, but the act of asking signals that the buyer understands the seasonal dynamics and is tracking performance accordingly.

The second step is to track delivery performance by quarter, not by annual aggregate. A supplier who delivers 85% on-time overall might deliver 95% on-time in Q1, 90% in Q2, 80% in Q3, and 70% in Q4. That pattern reveals systematic seasonal compression, and it should inform procurement decisions. Buyers who identify this pattern can adjust their order timing—placing Q4 campaign orders in July instead of September—or negotiate explicit seasonal buffers into contracts.

The third step is to build seasonal lead time extensions into internal planning. If historical data shows that Q4 orders consistently take 50% longer than quoted, then an "eight weeks" quote in September should be treated as a "twelve weeks" estimate for planning purposes. This buffer does not eliminate the risk of late delivery, but it reduces the likelihood of campaign deadline failures and provides time to source alternatives if delays occur.

The fourth step is to diversify supplier base by peak season capacity. A buyer who sources all custom bags from a single offshore supplier is fully exposed to that supplier's Q4 capacity constraints. A buyer who splits orders between an offshore supplier (for cost efficiency) and a UK-based supplier (for speed and flexibility) can use the UK supplier for time-sensitive Q4 campaigns and the offshore supplier for less time-critical orders. This strategy increases per-unit costs but reduces campaign risk.

The seasonal lead time compression problem will persist as long as competitive pressure incentivizes suppliers to quote optimistic timelines and buyers lack the data to challenge those quotes. But buyers who recognize the pattern, ask the right questions, and adjust their planning accordingly can avoid the most severe consequences. The Manchester retail chain that missed Black Friday now places Q4 campaign orders in July, explicitly asks for "worst-case Q4 lead time," and maintains a relationship with a UK-based supplier for emergency orders. Their per-unit costs have increased by 8%, but their campaign deadline failure rate has dropped from 40% to 5%. That trade-off, in their assessment, is worth making.