When procurement teams finalise material specifications for custom promotional bags, they operate under a reasonable assumption: that specifying "280gsm cotton canvas" or "600D Oxford polyester" locks in a precise material that will arrive exactly as described. The specification sheet becomes a contract, and the contract, they believe, guarantees consistency.

In practice, this assumption creates one of the most persistent quality gaps in custom bag production—and it's a gap that rarely surfaces until bulk orders arrive with subtle but consequential differences from the approved sample.

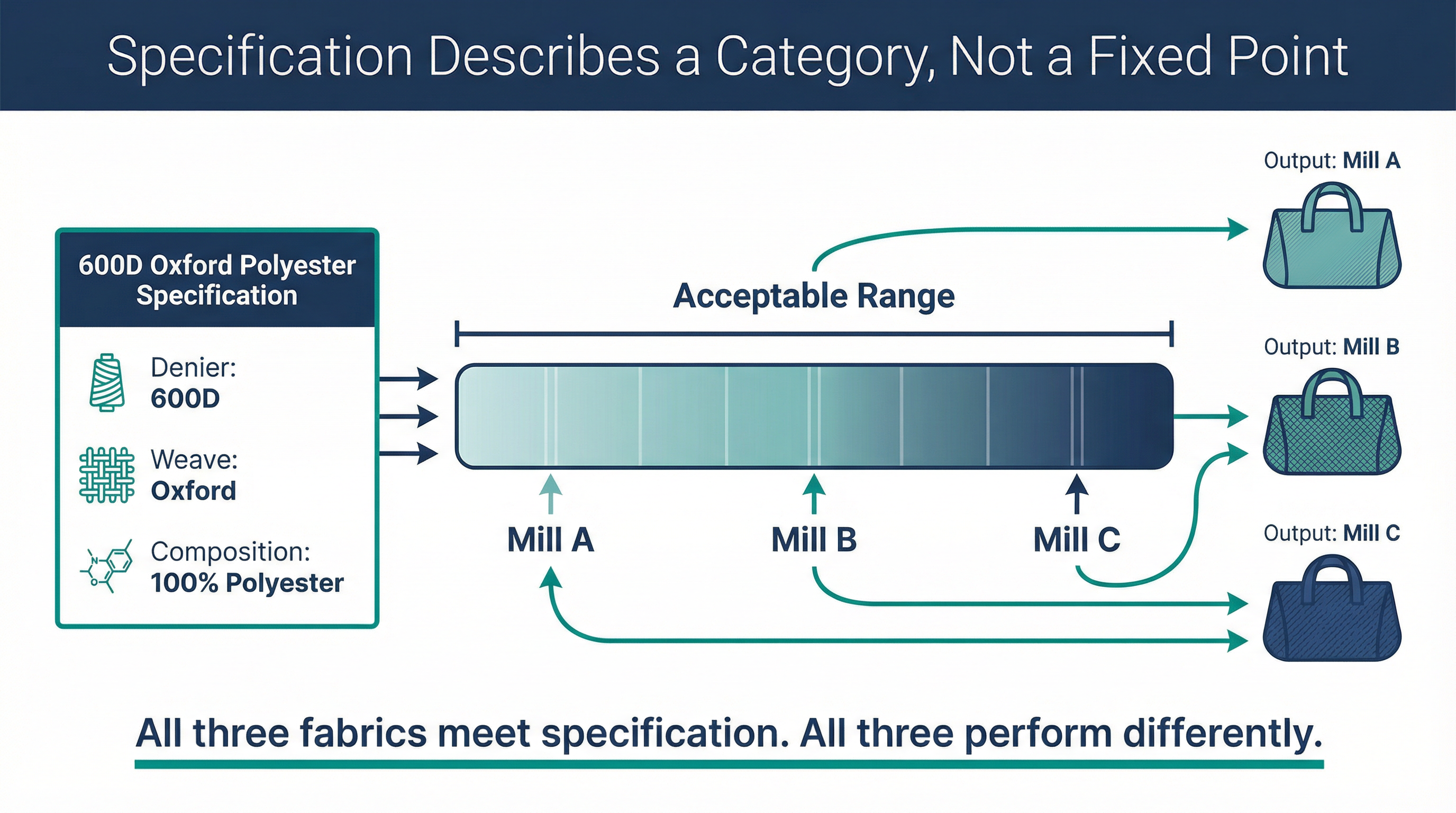

The issue isn't that suppliers ignore specifications. The issue is that material specifications describe categories of materials, not specific products. Understanding this distinction is essential for any organisation managing custom bag orders where brand consistency and quality perception matter.

How material specifications describe ranges rather than fixed points, creating variance between sample and bulk production

How material specifications describe ranges rather than fixed points, creating variance between sample and bulk production

Consider the specification "600D Oxford polyester"—a standard choice for promotional tote bags and corporate gift bags across the UK market. This specification appears precise: 600 denier, Oxford weave, polyester composition. In reality, this single specification encompasses materials with meaningfully different characteristics. The weave density can vary. The coating—PU, PVC, or none—affects water resistance, hand feel, and printing adhesion. The yarn quality influences durability and colour fastness. Two fabrics that both technically qualify as "600D Oxford polyester" can look and perform quite differently in finished bags.

This variance isn't a defect or a sign of supplier negligence. It's an inherent characteristic of how textile specifications work. Specifications set boundaries, not fixed points. A fabric that falls within those boundaries meets the specification, even if it differs from the fabric used in the sample.

The practical consequence emerges during bulk production. The sample was made with a specific roll of fabric from a specific mill at a specific time. When bulk production begins—often weeks or months later—the factory sources fabric that meets the same specification but may come from a different mill, a different batch, or a different production run. The specification is satisfied. The fabric is different.

For UK businesses ordering custom bags for corporate gifting or promotional campaigns, this variance manifests in ways that are difficult to quantify but easy to perceive. The bag feels slightly different in hand. The colour appears marginally off under certain lighting. The logo print adheres differently to the surface. None of these differences constitute a specification failure, yet collectively they create a gap between expectation and delivery.

The misjudgment often begins at the specification stage itself. Procurement teams focus on measurable parameters—GSM for cotton, denier for polyester, thread count, composition percentage—because these parameters are objective and verifiable. What gets overlooked are the performance characteristics that specifications don't capture: how the fabric behaves during printing, how it responds to stitching tension, how it ages with use, how it feels to the end recipient.

This is where the customization process becomes more complex than it initially appears. Understanding how material selection integrates with the broader production timeline helps organisations anticipate where specification-to-production gaps typically emerge and how to mitigate them before they affect final quality.

The challenge intensifies when multiple components are involved. A custom bag isn't just fabric—it's fabric plus handles, zippers, linings, reinforcements, and printing. Each component has its own specification, and each specification describes a range rather than a fixed point. When these ranges combine, the cumulative variance can be substantial. A bag where every component meets specification can still differ noticeably from the approved sample because the tolerances stack.

Tolerance stacking is a concept familiar to manufacturing engineers but often unfamiliar to procurement teams. If the fabric is at the lighter end of its acceptable GSM range, the handles are at the thinner end of their width tolerance, and the printing ink is at the lighter end of its colour tolerance, the finished bag—while technically compliant—will feel and look different from a sample where each component happened to fall at the centre of its range.

This isn't a failure of quality control. It's a structural characteristic of manufacturing with specifications. The solution isn't tighter specifications—which increase cost and reduce supplier flexibility—but rather a shift in how specifications are understood and communicated.

Experienced procurement teams learn to specify by outcome rather than solely by parameter. Instead of only stating "280gsm cotton canvas," they add performance requirements: "must match sample hand feel," "must achieve minimum 4/5 colour fastness rating," "must support screen printing with specified ink adhesion." These outcome-based specifications give factories clearer guidance on what actually matters and provide a basis for quality assessment that goes beyond checking numbers.

The timing of material confirmation also matters more than many buyers realise. Confirming material specifications at the quotation stage is standard practice. Confirming actual material availability—and ideally reserving specific fabric lots—after sample approval but before production commitment is less common but significantly more effective at reducing variance. When the factory knows exactly which fabric will be used for bulk production, they can produce a pre-production sample from that specific material, giving buyers a final verification opportunity before full production begins.

For UK businesses navigating custom bag orders, the practical implication is straightforward: treat material specifications as starting points for conversation, not endpoints for contracts. Ask suppliers what variance is normal within the specification. Request information about which mills supply their fabric and whether batch-to-batch consistency is monitored. Understand that "meets specification" and "matches sample" are related but not identical standards.

The gap between specification and consistency isn't a problem to be eliminated—it's a characteristic to be managed. Organisations that recognise this distinction make better sourcing decisions, set more realistic expectations, and ultimately receive custom bags that align more closely with their brand standards and quality requirements.

The situation becomes particularly acute when dealing with cotton canvas—a material frequently specified for eco-friendly promotional bags and corporate gifts where sustainability messaging is part of the brand value proposition. Cotton canvas specifications typically include GSM (grams per square metre), weave type, and sometimes thread count. What these specifications don't capture is the cotton's origin, the spinning method, the finishing treatment, or the natural variance inherent in agricultural products.

A 280gsm cotton canvas from one mill may have a tighter weave and smoother surface than a 280gsm canvas from another mill, even though both meet the same specification. The first may print beautifully with crisp logo reproduction; the second may absorb ink differently, producing slightly softer edges. Both are correct. Both meet specification. They're not the same.

This variance is amplified by the global nature of textile supply chains. The fabric specified in a UK buyer's order may be woven in China, India, Pakistan, or Turkey. Each region has different cotton sources, different spinning traditions, and different finishing standards. A specification that works predictably with one supply chain may produce different results when sourced from another—even though the technical parameters remain identical.

The colour matching challenge illustrates this principle clearly. Buyers specify Pantone colours expecting exact reproduction. In practice, Pantone matching depends not just on the ink but on the substrate. The same Pantone colour printed on two fabrics that both meet "280gsm cotton canvas" specifications can appear noticeably different because the fabrics absorb and reflect light differently. The specification guarantees the ink colour; it doesn't guarantee how that colour will appear on the specific fabric batch used for production.

Experienced quality consultants approach this challenge by distinguishing between specification compliance and outcome achievement. Specification compliance is binary—the material either meets the stated parameters or it doesn't. Outcome achievement is contextual—the material either produces the desired result in the finished product or it doesn't. A material can be compliant without achieving the outcome, and this gap is where quality disputes typically originate.

The solution isn't to abandon specifications—they remain essential for communication and quality control. The solution is to layer outcome requirements on top of parameter specifications. For custom promotional bags, this might mean specifying not just "600D Oxford polyester" but also "must achieve minimum 3.5 Martindale abrasion resistance" or "must maintain colour consistency within Delta E 2.0 across production run."

These outcome-based additions transform specifications from category descriptions into performance contracts. They give factories clearer guidance on what matters and provide buyers with measurable standards for acceptance. They also shift the conversation from "did you use the right material?" to "did the material perform as required?"—a more productive frame for quality management.

For UK businesses sourcing custom bags, the practical takeaway is to invest time in the specification stage that goes beyond selecting material parameters. Understand what variance is normal. Define what outcomes matter. Build verification points into the production timeline. And recognise that the gap between specification and consistency isn't a supplier problem to be solved—it's a manufacturing reality to be managed.

The organisations that navigate custom bag production most successfully are those that treat material specifications as the beginning of a quality conversation, not the end of it. They ask questions about supply chain consistency. They request pre-production samples from actual production materials. They define acceptance criteria that include subjective assessment alongside objective measurement. And they build relationships with suppliers who understand that meeting specification is necessary but not sufficient for delivering quality.

This approach requires more engagement than simply issuing a specification sheet and expecting compliance. But for businesses where custom bags represent brand identity—whether for corporate gifting, employee onboarding, or promotional campaigns—the investment in specification sophistication pays dividends in consistency, quality perception, and ultimately, brand value.